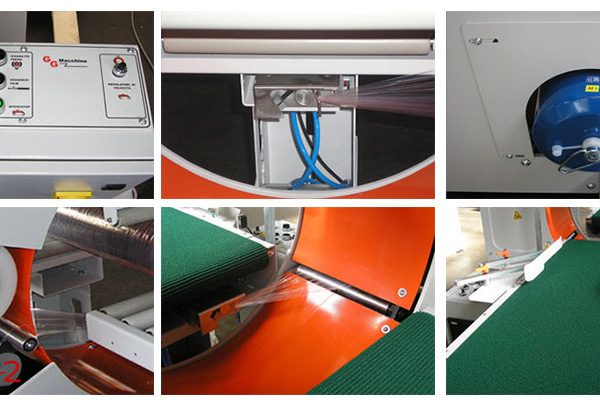

Description

Optional

Rollers PVC coated

This optional is recommended if needed that the products flow on a surface which is soft and doesn’t scratch, allowing this way to protect the surface of the product

Manual pressure with free roller PVC coated

This optional allows a more functional packaging especially for very light products; positioning the pressure at the desired height, dependent on the size of the product, it has the task to keep it stationary while the ring rotates during the wrapping phase, avoiding any bounce of the product.

Lateral guides with rollers PVC coated

It is appropriate to use this option when there is the necessity to wrap a product with a delicate surface, which could be scratched by the standard sheet lateral guides.

Pre – Stretch film

It can be supplied on all automatic and semi-automatic models. It reduces the consumption of the stretch film by 100%. Allows a better packaging at a lower cost.